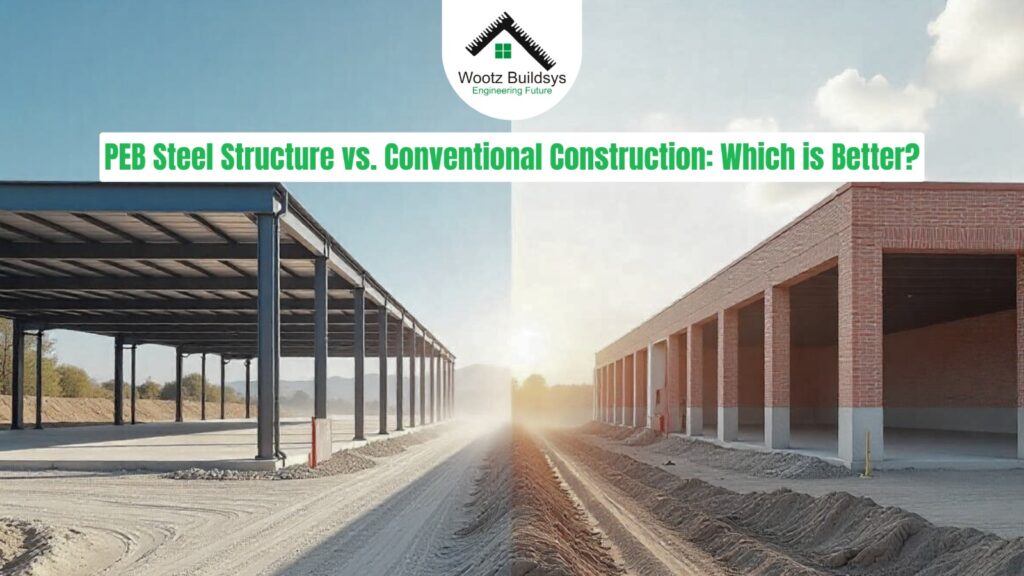

The construction industry has seen significant transformations over the years, with technological advancements leading to faster, more efficient, and sustainable building solutions. Among the most notable innovations in recent years is Pre-Engineered Buildings (PEB) — an approach that contrasts traditional construction methods in terms of speed, cost, and durability. As modern needs evolve, PEB Steel Structure are becoming increasingly popular in comparison to conventional construction. But which one should you choose for your project? Let’s dive deeper into both methods to help you make an informed decision.

Understanding PEB Steel Structures

A Pre-Engineered Building (PEB) is a building structure designed and fabricated off-site in a factory setting. The various components, such as steel frames, columns, and roof panels, are prefabricated and then transported to the site for assembly. PEBs are typically made from high-quality steel, which gives the structure its strength, flexibility, and durability.

One of the main advantages of a PEB is that the components are pre-designed according to the building’s requirements. This approach significantly reduces construction time and enhances the quality of the final product. PEB steel structures are ideal for industrial facilities, warehouses, commercial buildings, and large-scale infrastructure projects.

Understanding Conventional Construction

Conventional construction, on the other hand, is the traditional method of building structures. This approach involves the use of materials such as concrete, brick, timber, and steel. All construction work is done on-site, from the foundation to the roofing, which can make the process longer and more complex. Traditional construction methods have been around for centuries and are still widely used for residential homes, small offices, and other standard building projects.

In conventional construction, the design and construction happen simultaneously, often leading to increased project timelines. The on-site building process requires skilled labor, heavy machinery, and raw materials that need to be transported to the site.

Key Differences Between PEB and Conventional Construction

Let’s take a closer look at the primary differences between PEB Steel Structure and conventional construction methods.

1. Construction Time

- PEB Steel Structure: PEBs are pre-fabricated in a controlled factory environment, which allows for faster construction. Since the parts are pre-designed and ready to assemble, the overall time spent on-site is minimized. In many cases, PEBs can reduce construction time by up to 50%, making them an ideal choice for projects with tight timelines.

- Conventional Construction: Traditional construction takes much longer, as the entire process is completed on-site. Materials need to be procured, and workers must build each part from scratch. Moreover, construction can be delayed due to weather conditions or supply chain issues, which can lead to cost overruns and time delays.

2. Cost-Effectiveness

- PEB Steel Structure: PEBs are often more cost-effective than conventional construction. Since much of the work is completed in a factory setting, labor costs are lower, and material wastage is minimized. The speed of construction further reduces overall expenses, making PEBs a more affordable option, especially for large-scale projects.

- Conventional Construction: Conventional construction is typically more expensive due to higher labor costs and the need for on-site material procurement. Moreover, due to its longer timeline, there’s a higher risk of unexpected costs, including those caused by changes in design, delays, and inflation.

3. Durability & Strength

- PEB Steel Structure: Steel is a strong and durable material, making PEB Steel Structure highly resistant to harsh weather conditions, seismic activity, and corrosion. Steel buildings can withstand extreme temperatures, heavy winds, and even earthquakes, making them ideal for areas prone to natural disasters.

- Conventional Construction: While concrete and brick structures can be quite durable, they are often susceptible to wear and tear over time. These buildings may require frequent maintenance and repairs, especially in areas with extreme weather conditions. The longevity of conventional buildings is often contingent upon regular upkeep and repairs.

4. Flexibility & Customization

- PEB Steel Structure: PEBs offer remarkable flexibility in terms of design and customization. Since the components are pre-fabricated in the factory, changes and adjustments can be made more easily than in traditional construction. Furthermore, steel structures can be easily expanded or modified, providing long-term adaptability as the needs of the building change over time.

- Conventional Construction: While it is possible to customize conventional buildings, the process can be time-consuming and expensive. Modifications in a traditional structure often require significant changes to the on-site construction process, which may increase both the cost and timeline of the project.

5. Environmental Impact

- PEB Steel Structure: PEBs are more sustainable due to their efficient use of materials and the possibility of using recycled steel. Since the components are prefabricated, there is less waste on-site, and the controlled manufacturing process ensures that materials are used effectively. This leads to a smaller carbon footprint and less environmental impact.

- Conventional Construction: Traditional construction methods tend to generate more waste due to the on-site building process. Additionally, the materials used in conventional construction, such as cement and timber, often have a higher environmental impact. The extraction and processing of these materials contribute to resource depletion and carbon emissions.

Applications of PEB and Conventional Construction

Both PEB and conventional construction methods have their own set of applications.

- PEB Steel Structures: These are most commonly used in large-scale industrial and commercial projects, such as warehouses, factories, sports arenas, and aircraft hangars. They are also well-suited for applications that require quick turnaround times and cost-effective solutions.

- Conventional Construction: This method remains the go-to for residential buildings, small office spaces, and projects requiring specific architectural details. Conventional construction is preferred for traditional homes, luxury residences, and buildings with complex designs.

Which One Should You Choose?

When deciding between a PEB Steel Structure and conventional construction, several factors should be taken into account:

- Project Size: For larger projects, such as warehouses, industrial facilities, and commercial buildings, PEB steel structures offer significant advantages in terms of cost, speed, and durability.

- Budget: If you have a tight budget and need a cost-effective solution, a PEB steel structure is often the better choice. It allows for reduced labor costs, less material waste, and faster completion.

- Timeline: If your project requires fast delivery, a PEB is the way to go. With reduced construction time, you can expect a quicker handover of the finished structure.

- Design Complexity: For more intricate designs and customized architectural elements, conventional construction may be the better choice. Traditional methods offer more flexibility in creating detailed finishes.

Conclusion

Both PEB Steel Structure and conventional construction methods have their advantages, depending on your project needs. However, the efficiency, cost savings, and sustainability of PEBs make them an excellent choice for modern construction requirements. As the demand for quicker, more durable, and eco-friendly buildings grows, PEB steel structures are undoubtedly the future of the construction industry.

Frequently Asked Questions (FAQs)

1. Is a PEB Steel Structure stronger than conventional buildings?

Yes, PEBs are made from high-strength steel, making them more resistant to extreme weather conditions and seismic activities.

2. Can PEBs be used for residential purposes?

Yes, PEB technology is being adapted for modern residential buildings, offering faster and cost-effective housing solutions.

3. Do PEB structures require maintenance?

Minimal maintenance is needed due to the corrosion-resistant and durable nature of steel structures.

4. Are PEB steel structures energy efficient?

Yes, with proper insulation and energy-efficient roofing materials, PEBs can help reduce energy consumption.

5. How long does a PEB structure last?

With proper maintenance, PEB steel structures can last over 50 years.